- Inquiry

- Product

Consultation - Contract

Finalization - Material

Sourcing - Sample

Development - Production

- Quality

Inspection - Shipment &

Delivery

We offer OEM (Original Equipment Manufacturing) services, producing products that align with clients' brand identities. Our flexible production capabilities enable both small-batch and large-scale manufacturing, while a robust quality management system ensures stable and efficient operations.

We provide tailored ODM(Original Design Manufacturing) services, including product planning, R&D, and design. Our expertise spans trend analysis, production, quality control, and final shipment – offering a complete one-stop solution.

By controlling every stage of the process – from raw material selection to final delivery – we provide a seamless,

fully integrated jewelry manufacturing solution that meets the demands of global brands.

This approach enables us to maintain strict quality control, reduce lead times, and offer cost-effective, high-quality jewelry production

tailored to each client’s needs.

We operate an in-house quality laboratory to ensure every product meets our strict, consistent quality standards.

Our comprehensive testing process identifies potential defects early – before production is complete – ensuring the highest levels of durability and reliability in the final product.

An advanced X-ray fluorescence (XRF) analyzer used to precisely measure plating thickness and material composition, ensuring high-quality coatings

A simulation chamber that exposes materials to harsh environments to evaluate the corrosion resistance of coatings under extreme conditions.

We implement advanced testing equipment and strict quality control

processes to ensure precision, durability, and reliability in every piece

we manufacture.

: Ensures even and durable coatings.

: Measures coating and bonding strength.

: Evaluates chain strength and resistance.

: Tests durability under movement or shock.

: Checks impact resistance and structural integrity.

: Verifies performance of components like hinges and closures.

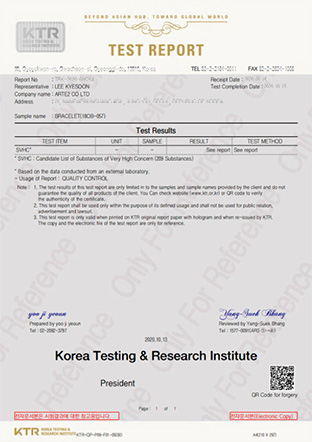

We adhere to internationally recognized standards such as SMETA by SGS and comply with SVHC requirements.

Fully Integrated Jewelry Manufacturing

for Unmatched Precision.