| Location | Total Gross Floor Area |

Factory 1 | Factory 2 | Capacity | Current Workforce |

|---|---|---|---|---|---|

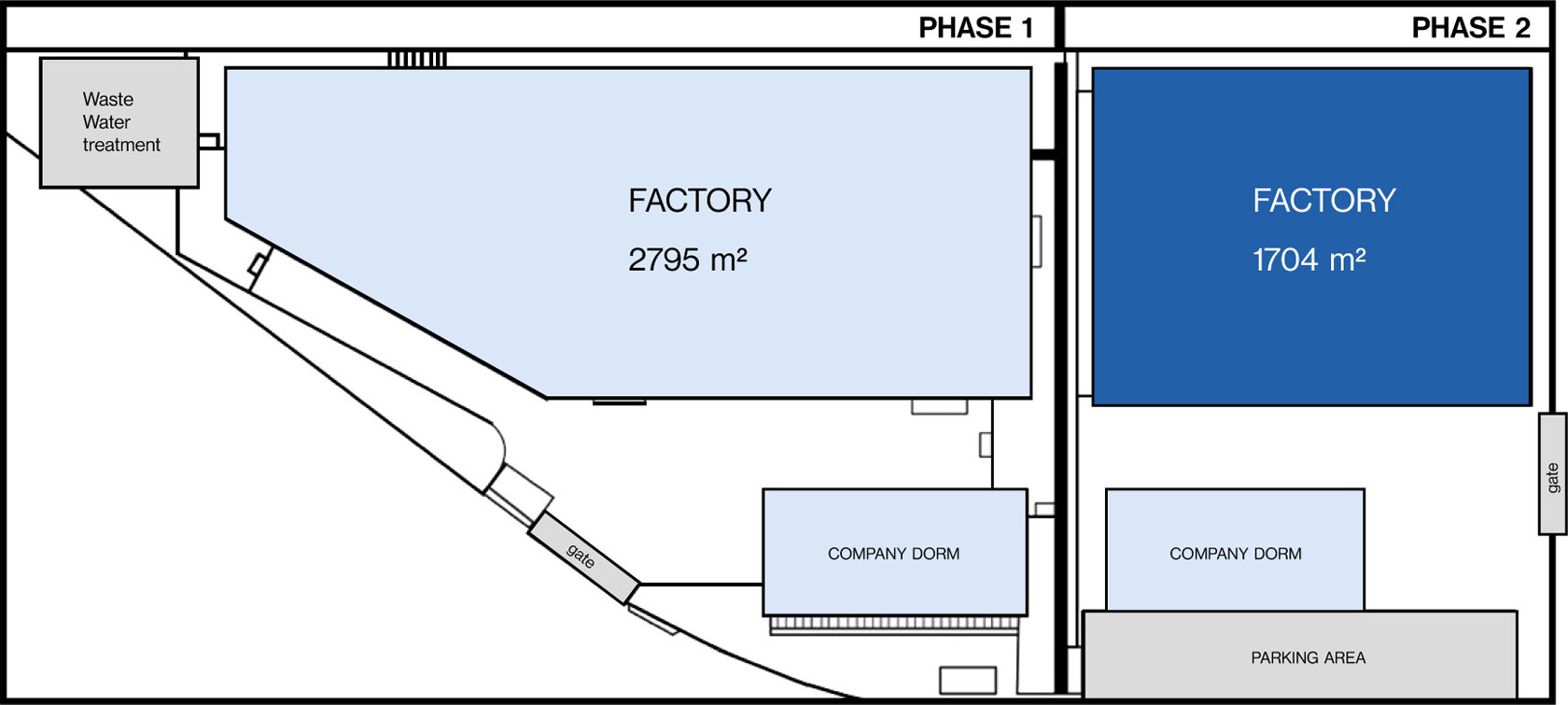

| Hanam, Vietnam | 10,000 ㎡ (1ha) | 2,795 ㎡ | 1,704 ㎡ | 300,000 pieces/month |

120 employees |

| Location | Hanam, Vietnam |

|---|---|

| Total Gross Floor Area |

10,000 ㎡ (1ha) |

| Factory 1 | 2,795 ㎡ |

| Factory 2 | 1,704 ㎡ |

| Capacity | 300,000 pieces/month |

| Current Workforce | 120 employees |

Factory 1: 2,987 ㎡ (currently in operation) currently in operation, spans 2,987 m², housing dedicated sections for casting, plating, assembly, and quality control.